Holy man, it's already going to be time for classes again! With classes comes responsibilities for work, projects, photography, paintings.. I do not think I will ever be BORED this semester, that's for sure! I will be in my Individual Art Review class for painting and that is going to be a whole other ballgame.. but in the meantime, I have been enjoying my 'freedom' and was invited to work in the Design Lab at my university pretty much all day yesterday :)

|

| unpacking... it was like Christmas! |

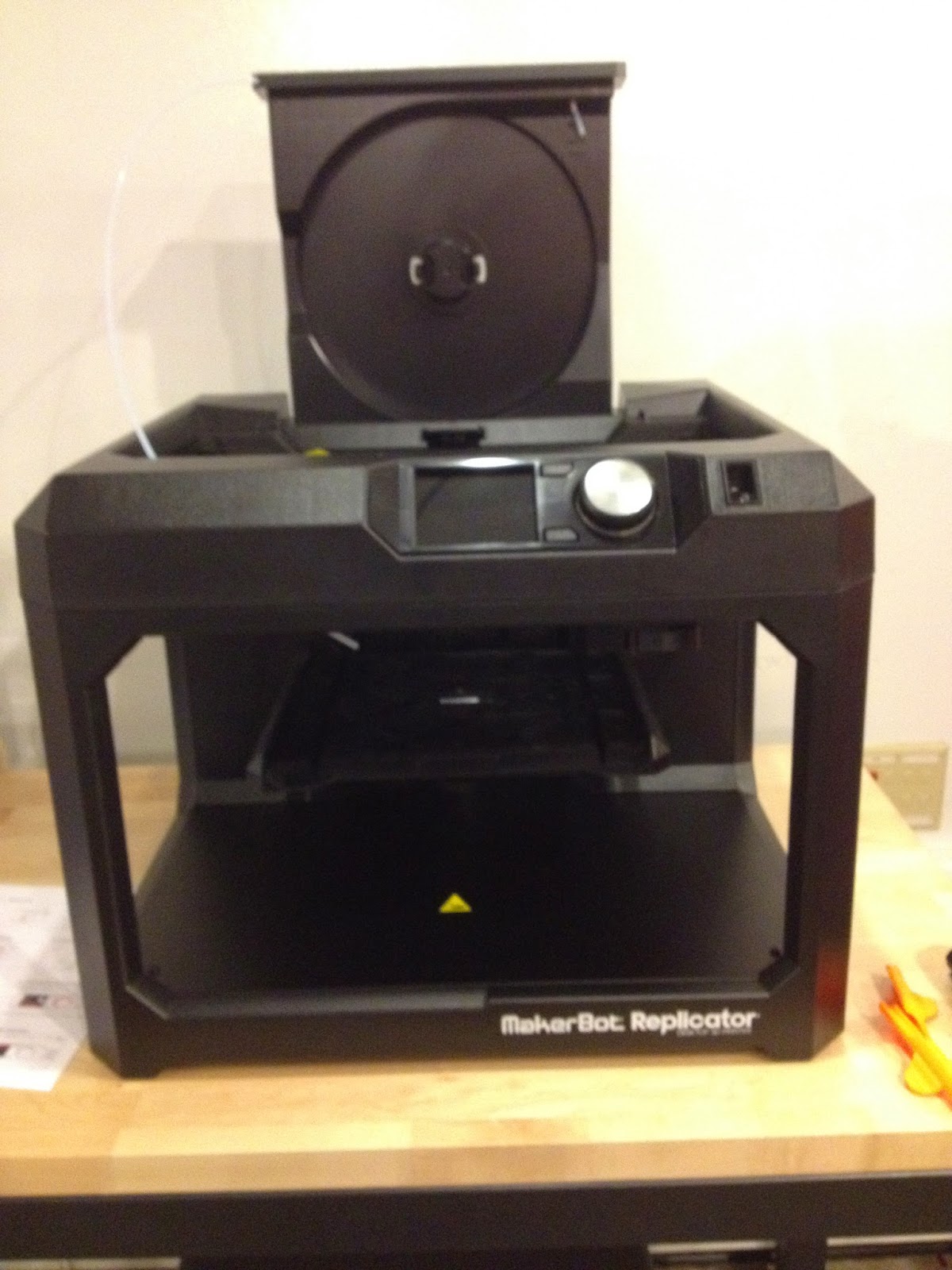

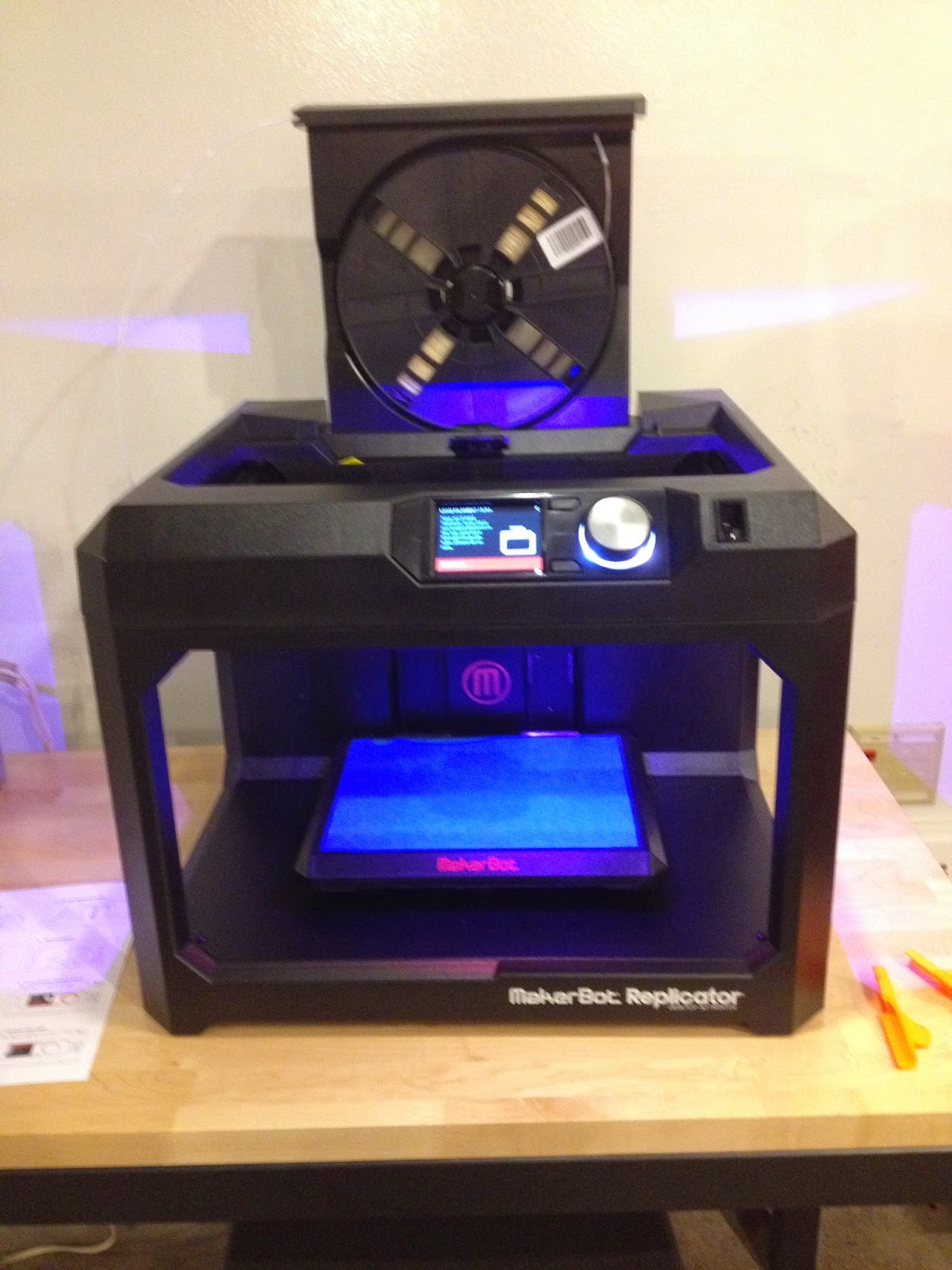

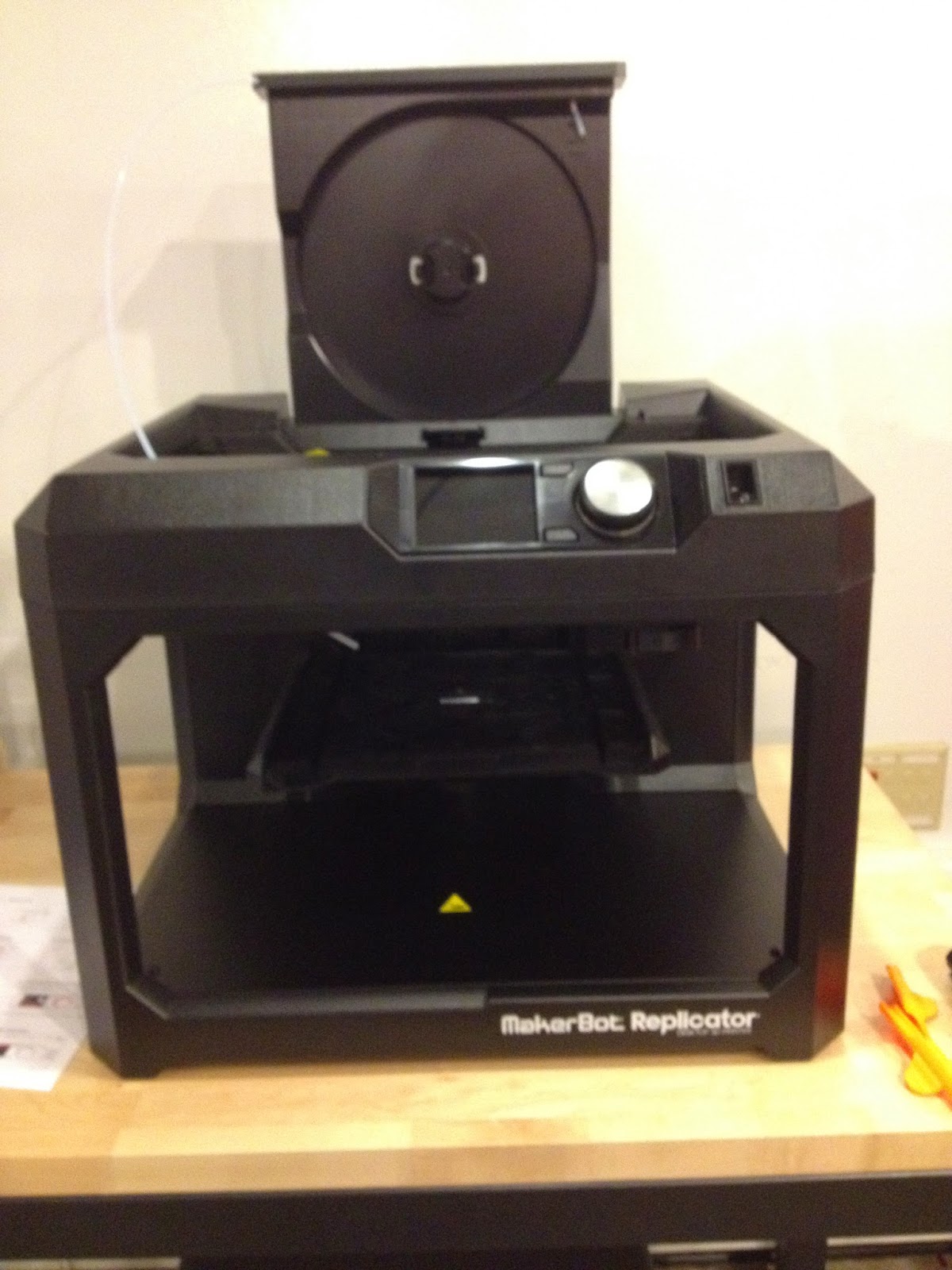

As you may (or may not) know, I was invited to present at the Michigan Art Education Association conference this year in Lansing, Michigan. My presentation will center around the educational applications of 3D printing in k-12 schools. I met with my Educational Technology professor (who got me all worked up about 3D printing in the first place!) and he had exciting news - he had a new

Makerbot Replicator to unpack and set up for the lab! He invited me to help him and then encouraged me to play and experiment with the printer - uuh YES. Just what I needed! It is important to me as a presenter to be actively involved in every step of the printing process so I can better understand the questions I will be asked - and the needs of teachers. That includes assembly and set up! Just like any other machine :)

|

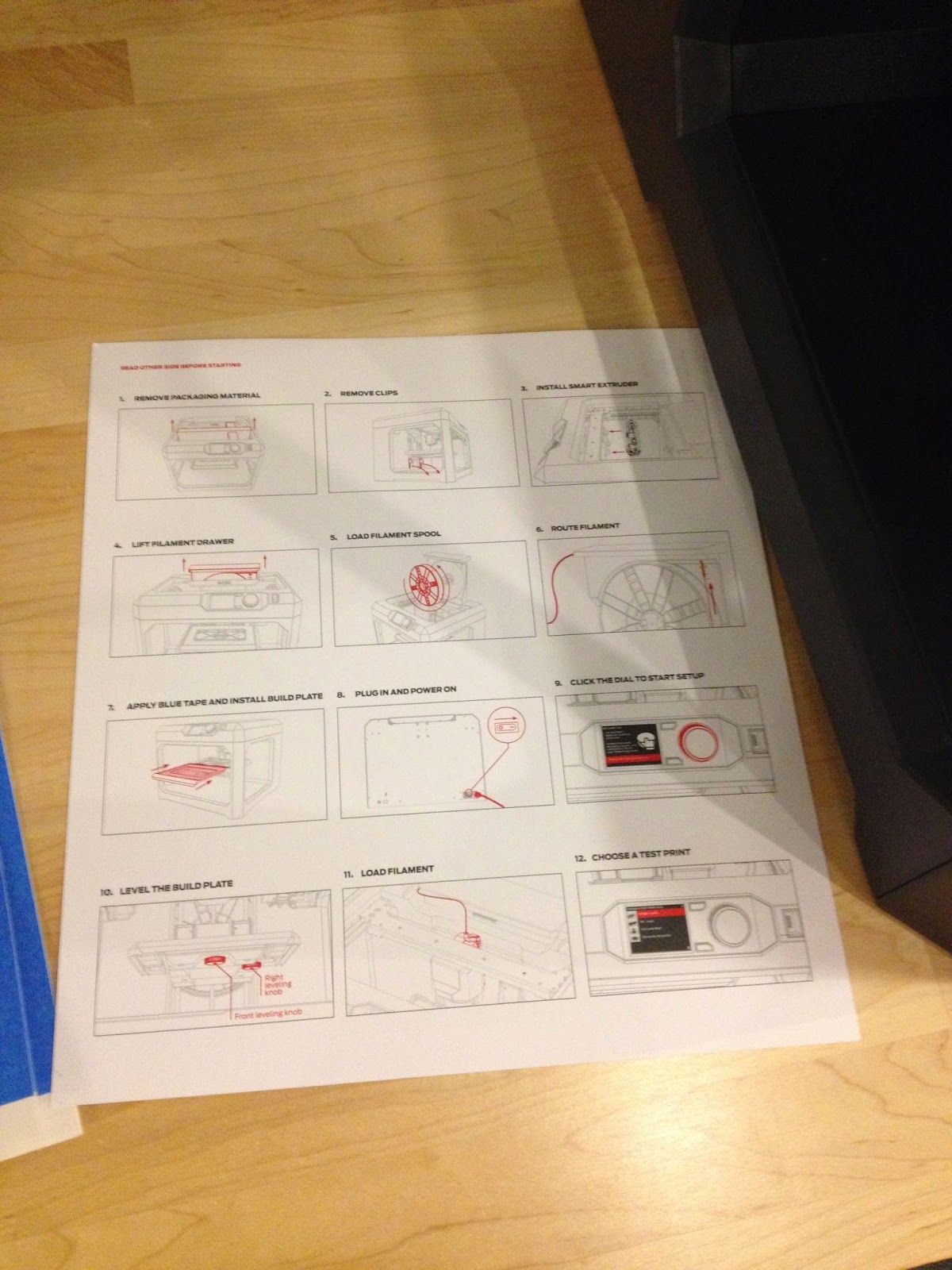

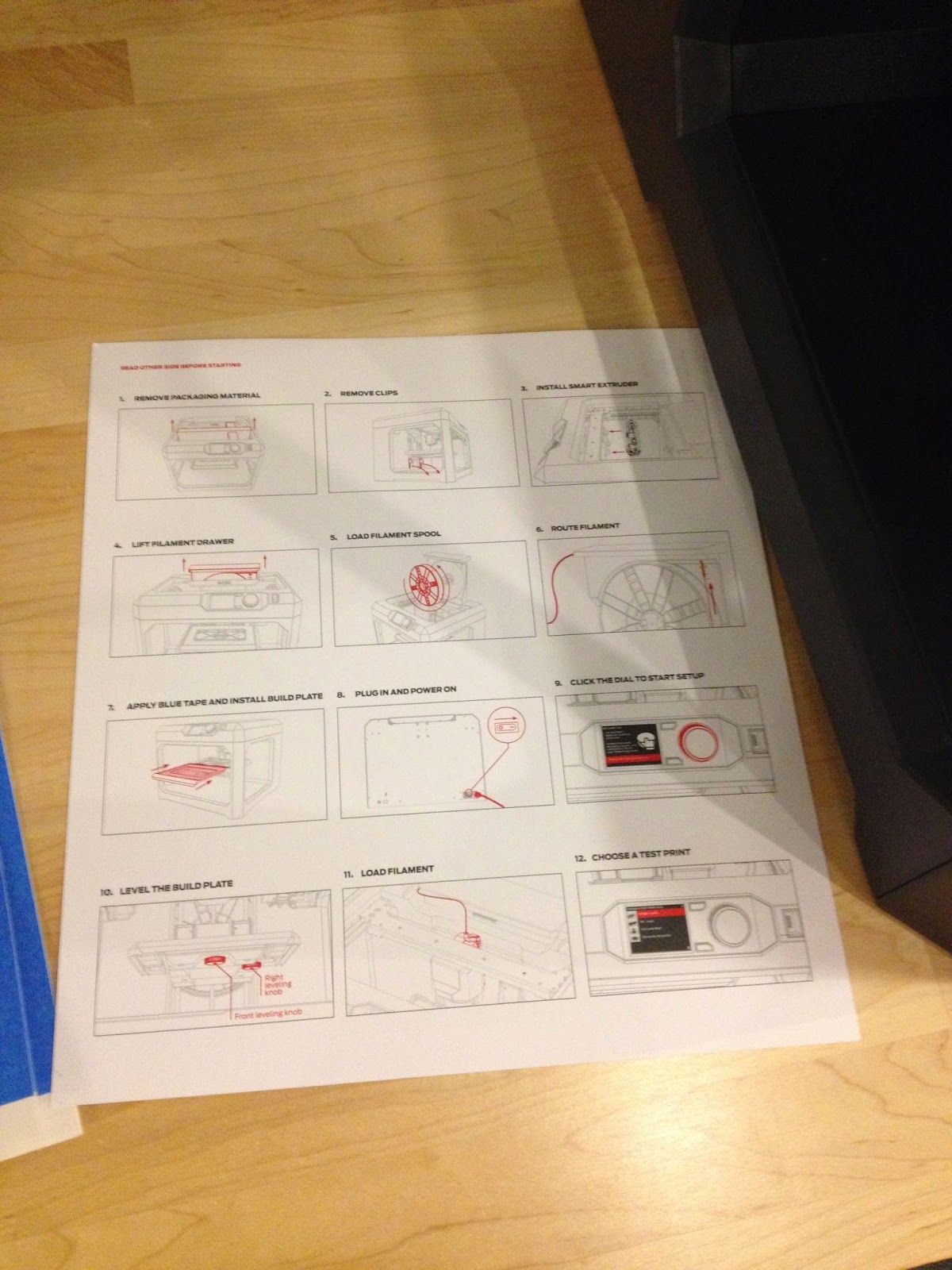

| the entire set of instructions. seriously - that's it! |

My presentation proposal read as follows:

"I would like to present on the potentials for learning with 3D Printing in the classroom, funding, and benefits of 3D printers in schools. I have been researching this technology for some time now. I will continue to experiment and gain more experience with 3D Printing before the conference. I have also contacted Makerbot, one of the leading manufacturers of 3D Printers, for advice, samples, and more information. I want to introduce art teachers to this cutting-edge and current technology and remove the stigma from 3D Printing in the art room."

Sound good?! I think so... back to the printer.

One thing I noticed right away was the simplicity of Makerbot's directions! In the packaging there was one (yes, one) sheet, back and front, of directions. And to be honest only one side had any directions on it! The other side was an inventory of shipped supplies and parts. The setup was SUPER easy - it only took about ten minutes to load filament, plug everything in, attach the extruder... easy easy! One of many reasons it is an appealing technology for teachers ;) In addition to simple set up, Makerbot has an active community of users and employees that are available to answer questions or troubleshoot issues you may have with your printer. In all my experiences in schools with technology initiatives, customer service is paramount in a classroom where you have 20+ kids all doing something at the same time and you RELY on your technology to teach and to learn. Being able to easily receive help with problems removes a lot of the stigma from introducing new technologies in schools...for me anyway!

|

| Getting ready to load filament..aka "ink" |

Loading the filament, called PLA (Polylactic Acid), was as simple as snapping in to the spool provided on the back of the printer. Polylactic Acid is a biodegradable type of plastic that is used in all different areas of production such as automotive parts, textiles, electronic components and even food preservation. It is bio-plastic, but think of it as fancy corn plastic. It stinks a little bit when you are printing because of the heat applied, but it's not a strong enough odor to bother you unless your face is right next to the machine (guilty). After that you have to feed filament through a plastic tube that eventually leads to the extruder (print head). The extruder (or as they call it, the "Smart Extruder") was a bit of a puzzle.. we figured out that a screw and a series of magnets is all it takes to become attached to the printer! No hardcore assembly required.

|

| smart extruder |

The extruder is one part of the printer that communicates with the firmware (computer) and feeds plastic filament into the printer. This will be a tricky thing to explain to the teachers but.. I will try to form an analogy to regular printing, I guess. The filament is like a solid ink cartridge and it is fed into the printer head (extruder) to create prints? Yeaaaa..I'm working on it lol

|

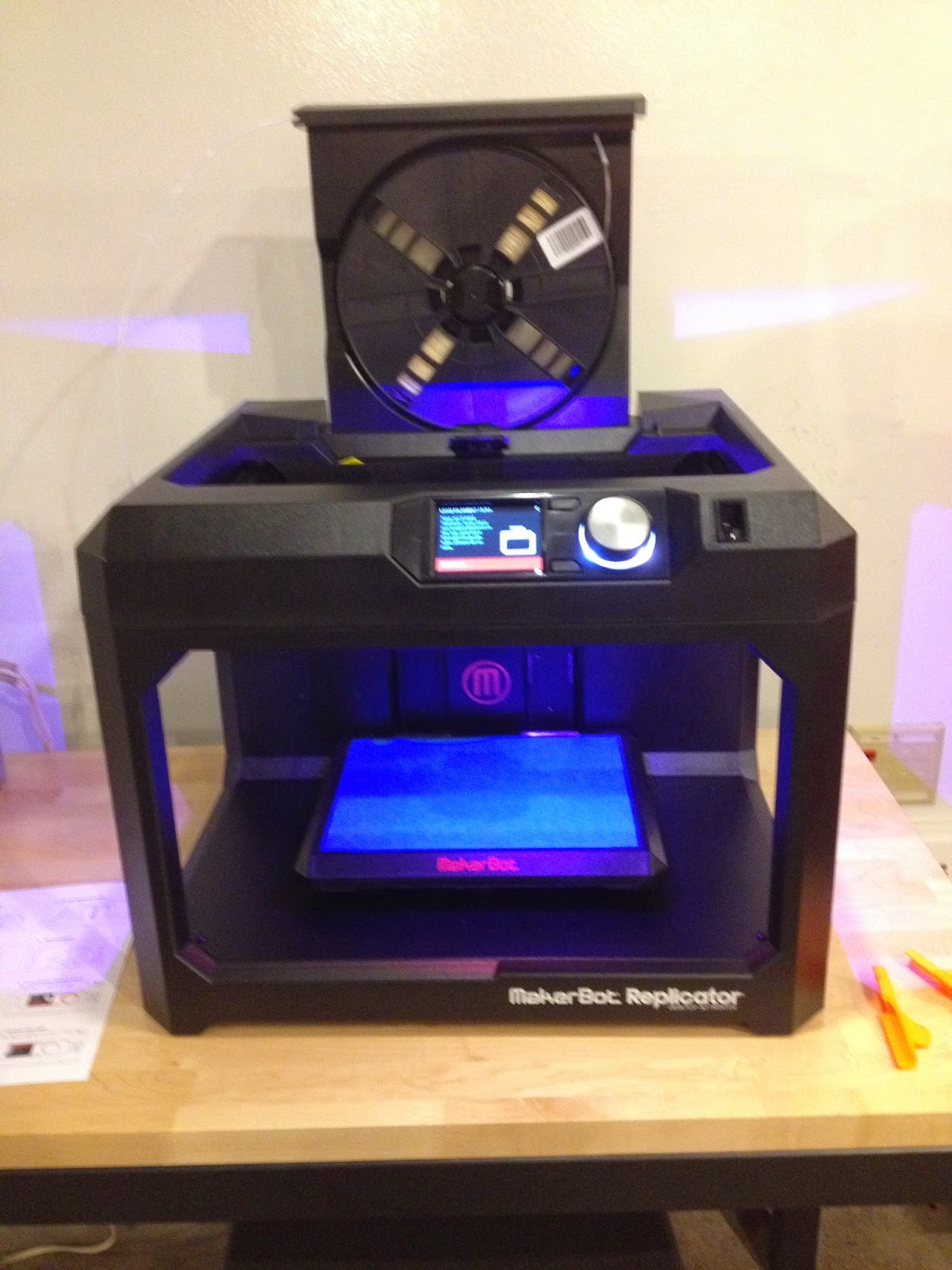

| almost ready! setting up the printing plate and loading...loading loading. |

One of the main issues I have read about in my research of 3D Printing is calibrating/leveling the printing plate. Makerbot has specialized sheets of blue tape which adhere to the glass print surface to prevent prints from sticking and to reduce damages from support material. Reading up on different types of printers, I discovered that Makerbot has one of the most efficient and easy methods to level the printing plate. Many DIY printers and some certain pre-assembled models have little to no guidance on how to level your print area - which leads to all sorts of problems. It would be like loading your inkjet printer with paper on a slant - no bueno. Your printing would be uneven and inconsistent which would lead to a sloppy, possibly over-inked print.

On the Makerbot, there are two knobs that you have to turn a certain way to level the print area - and the printer actually communicates with you when to start and stop! That step was the most time consuming and 'labor intensive' of them all... but then came the waiting!

|

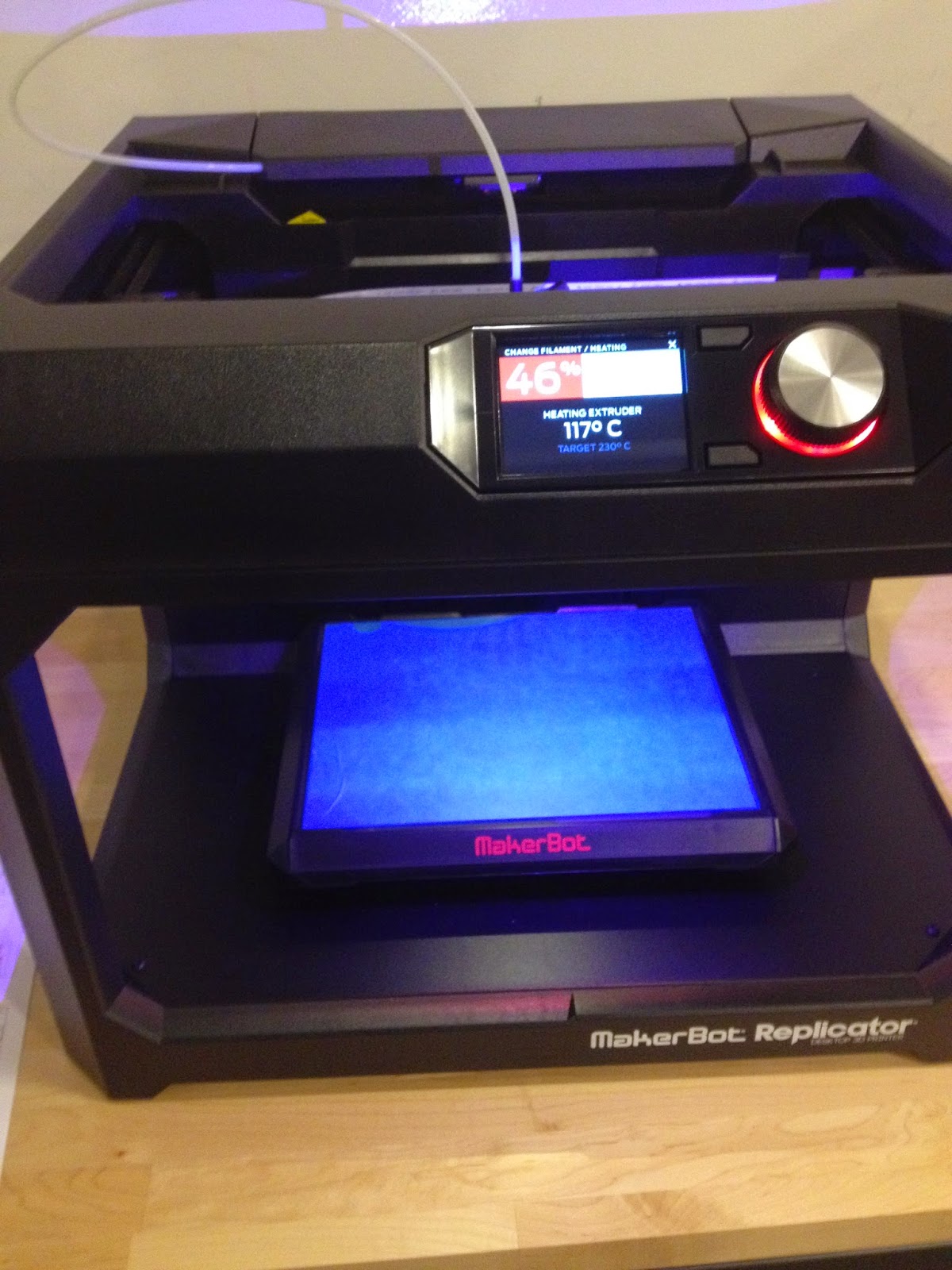

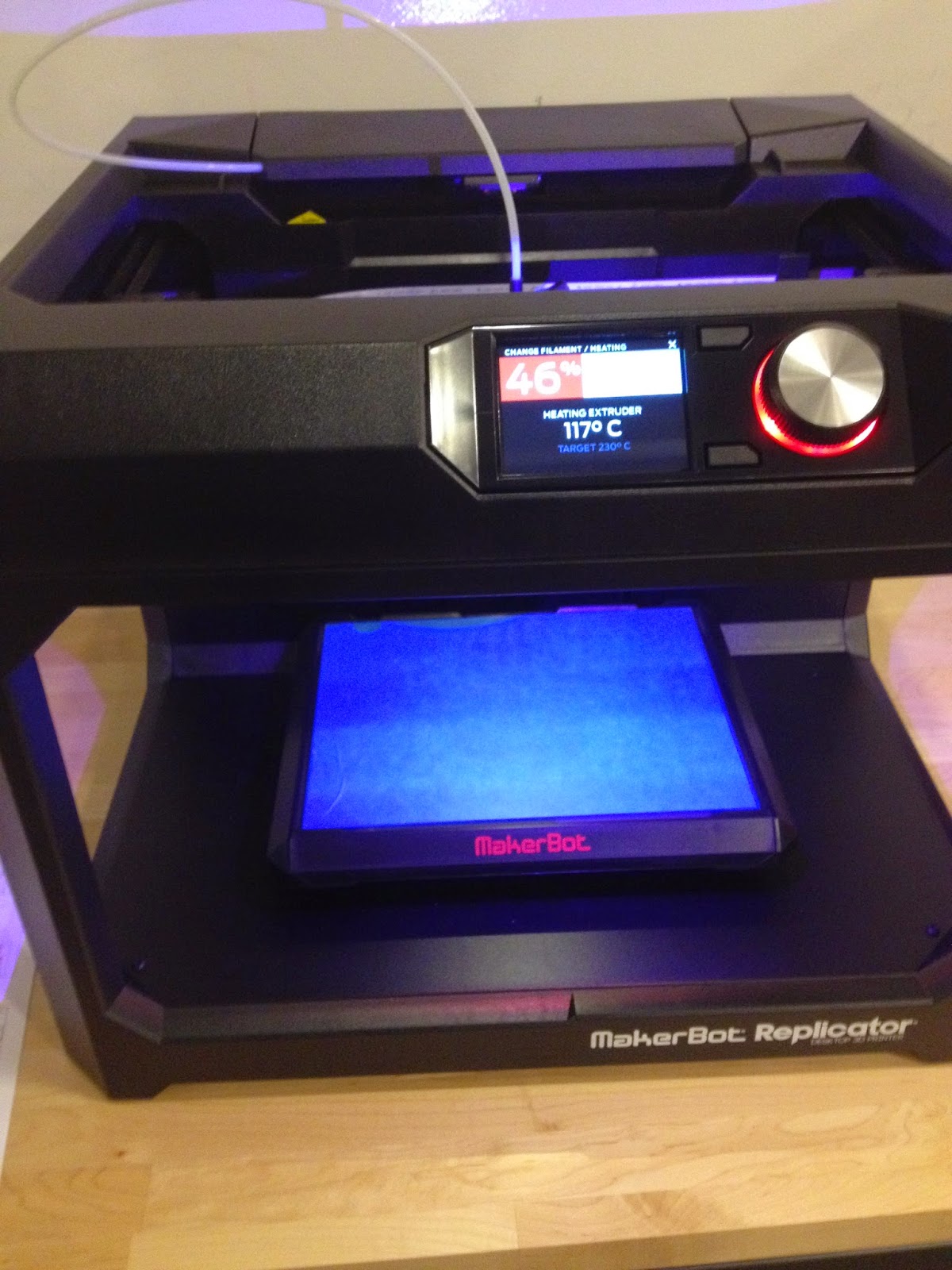

| waiting for the printer to heat up... takes a life age when you just wanna play! |

3D Printers do their thing by heating up the plastic filament in the Smart Extruder. The extruder is a heating element that communicates with the printer. Temperature inside the extruder increases gradually, allowing the filament to be heated evenly throughout and be prepared for printing. The plastic filament is pushed into the heating element, melted, and then pours out of the extruder into your computed shape or object. To use a food analogy, it looks like hot batter being poured for a funnel cake (mmmmm yes) but the funnel cake can become ANYTHING and is built up in layers. The computer tells the printer what direction to extrude filament and in what patterns/designs. So think of a double-decker or multi-story funnel cake. Think of it. Now clean yourself up because you're drooling! Okay, maybe that's just me...

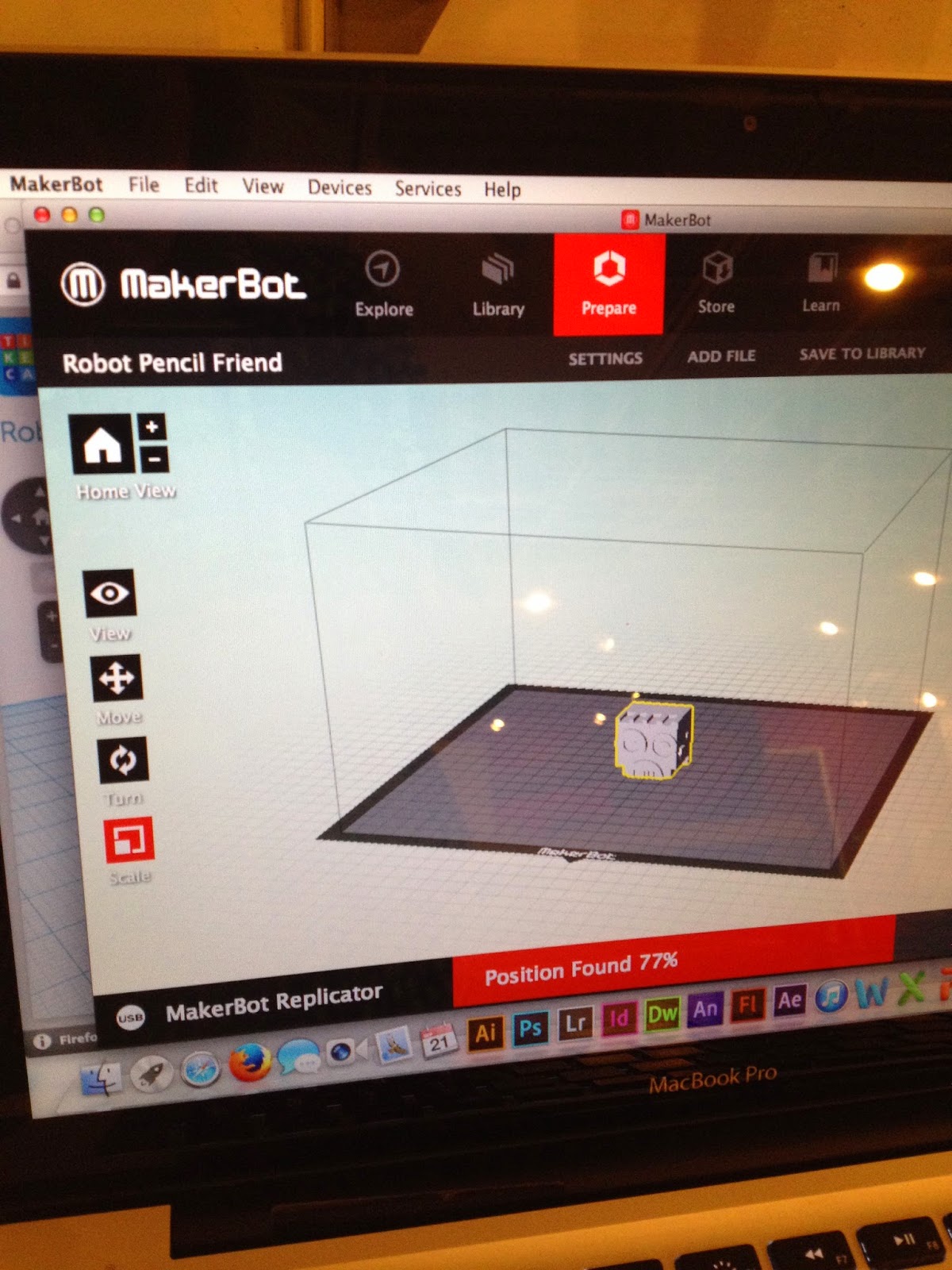

Makerbot is working on creating wireless capabilities for their printers - in a busy area like the university, the networks become pretty clogged up with chatter so we used a USB cable to connect to the printer. We also used an ethernet cable to connect to the internet. You can also save objects/designs onto a drive or card and transfer them to your printer. When I downloaded the Makerbot printing software I was provided a library to start with - and

Thingiverse! Thingiverse is another resource for printing - it is a huge hub for designers, artists, and 3Dprinting enthusiasts to share their projects with others. You can download the files and then the Makerbot software (or your printer's software) imports them for editing and printing.. it can be very technical designs or very simple templates. The choice is yours! In addition to downloading designs you can also outsource designs to printing companies such as

Shapeways and

iMaterialise. For teachers without the option to print in their classroom or school, outsourcing to printing companies is a viable option. But for me... I am going to want it in front of me haha

|

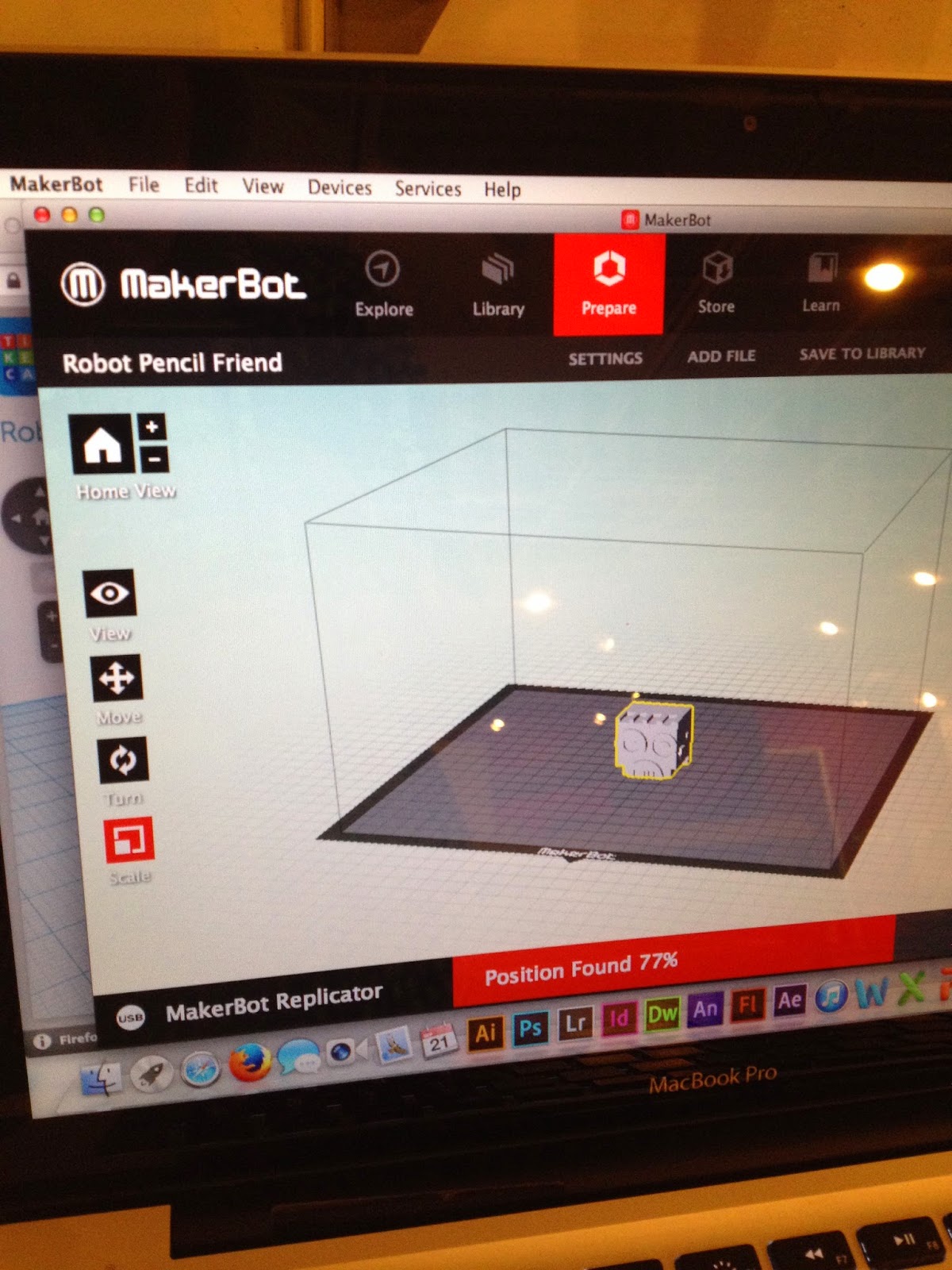

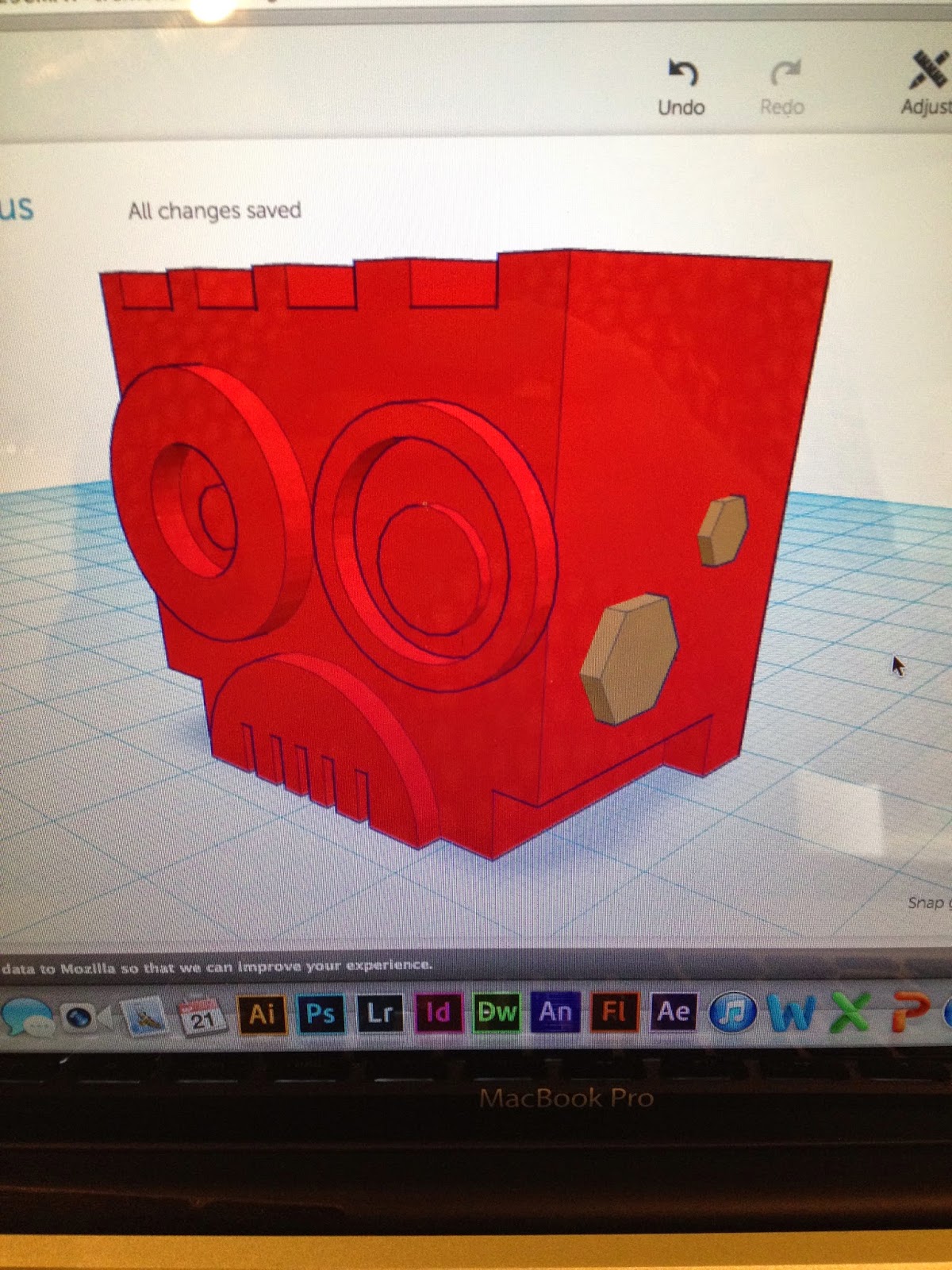

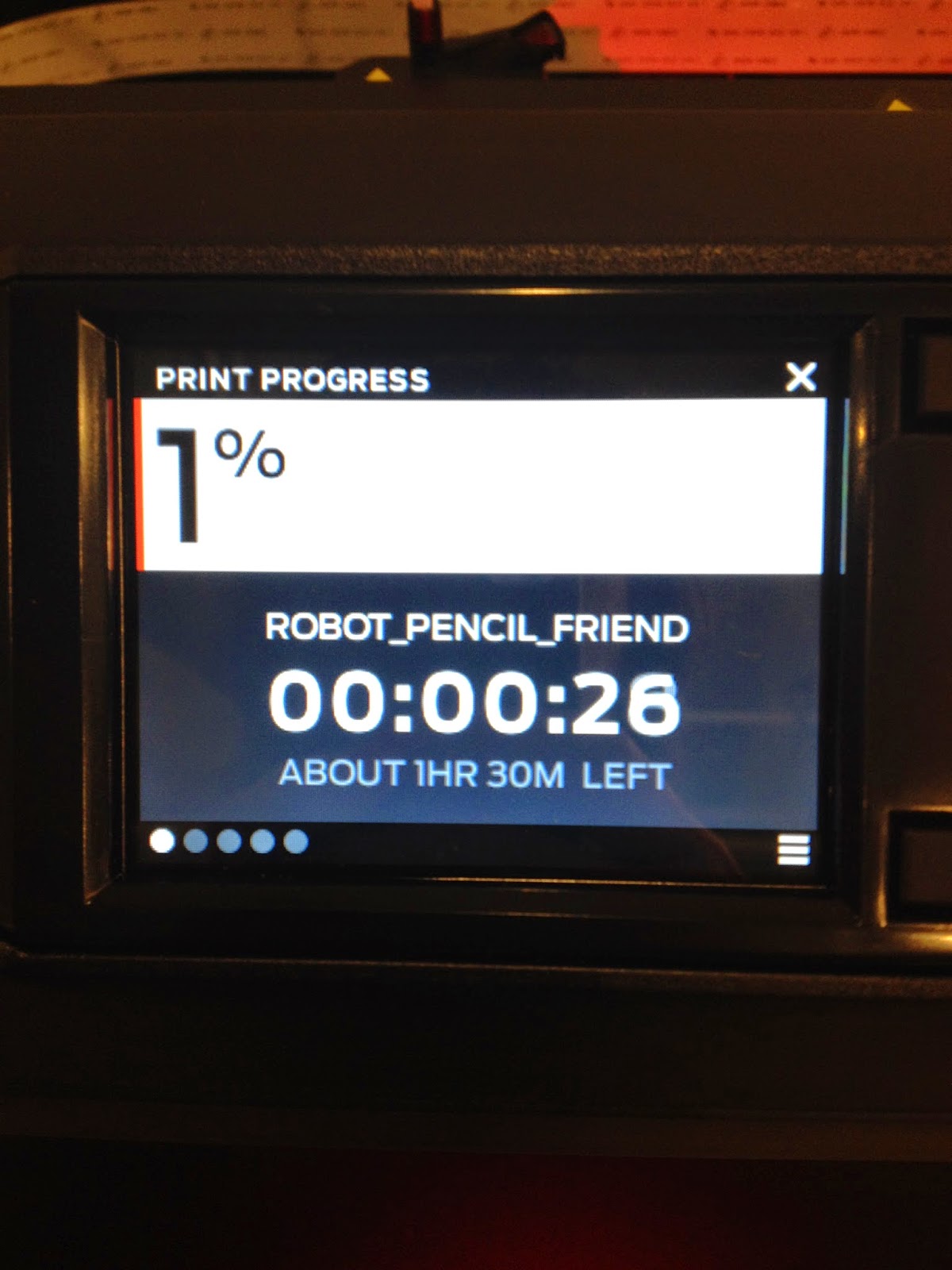

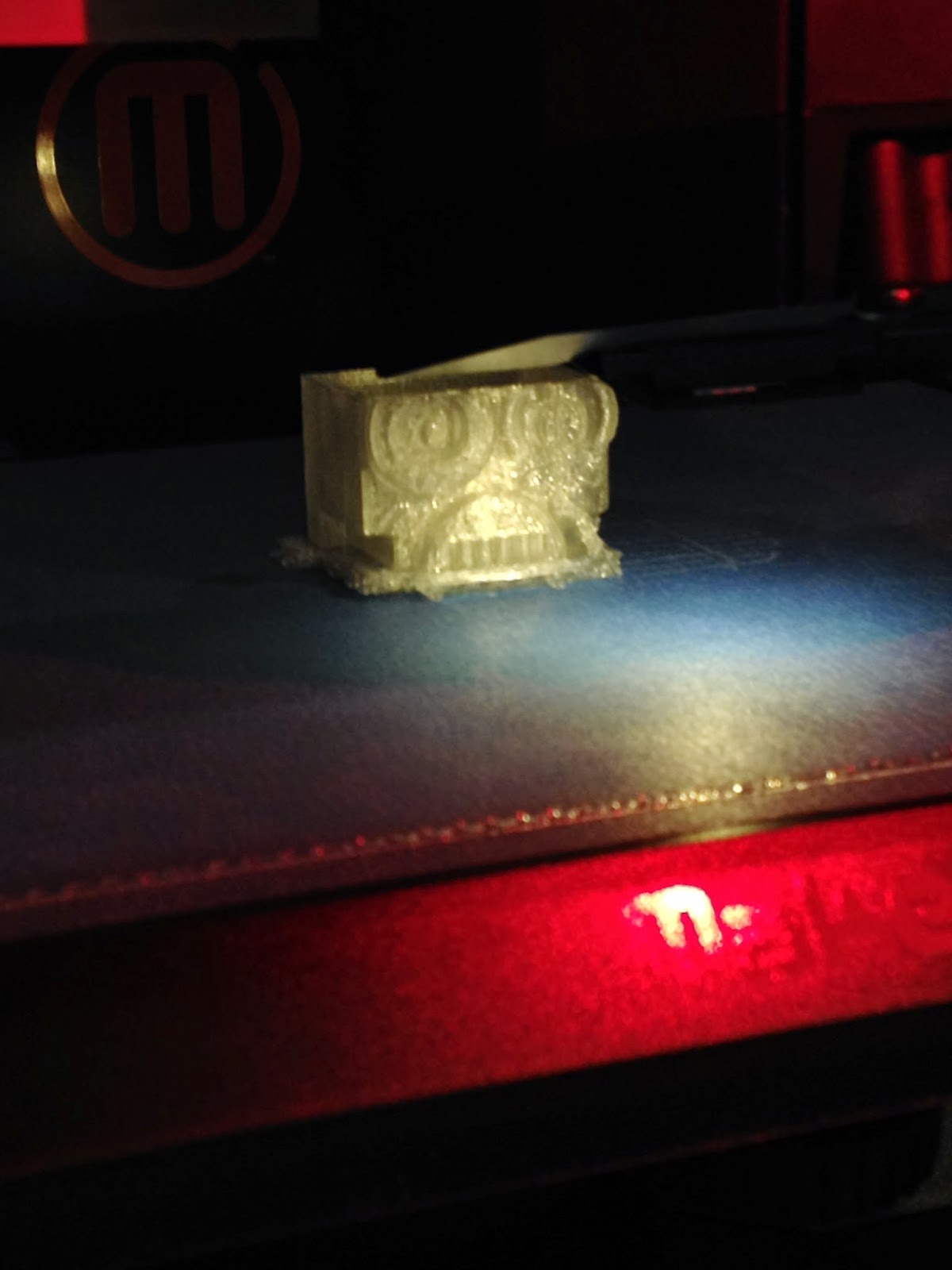

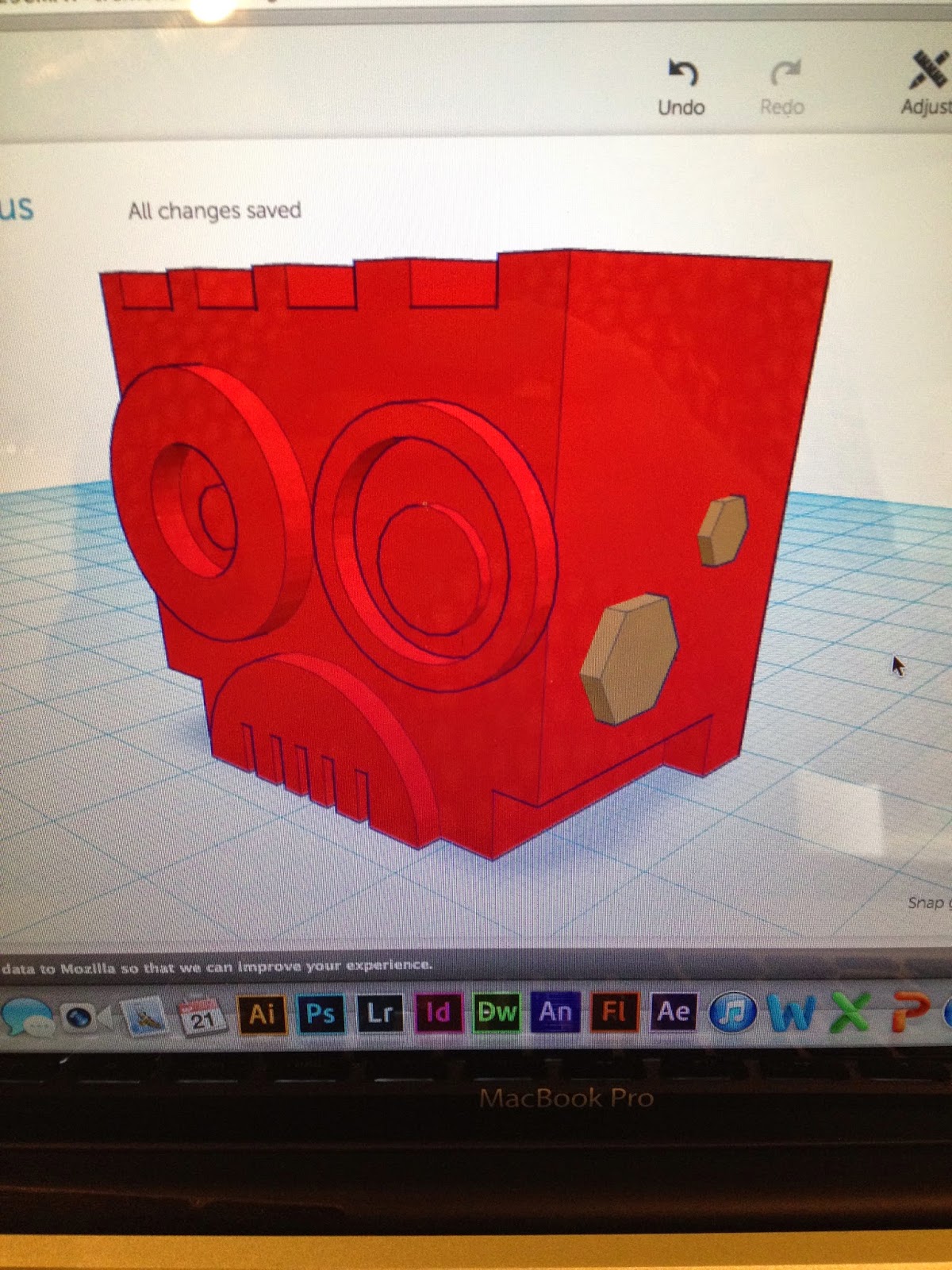

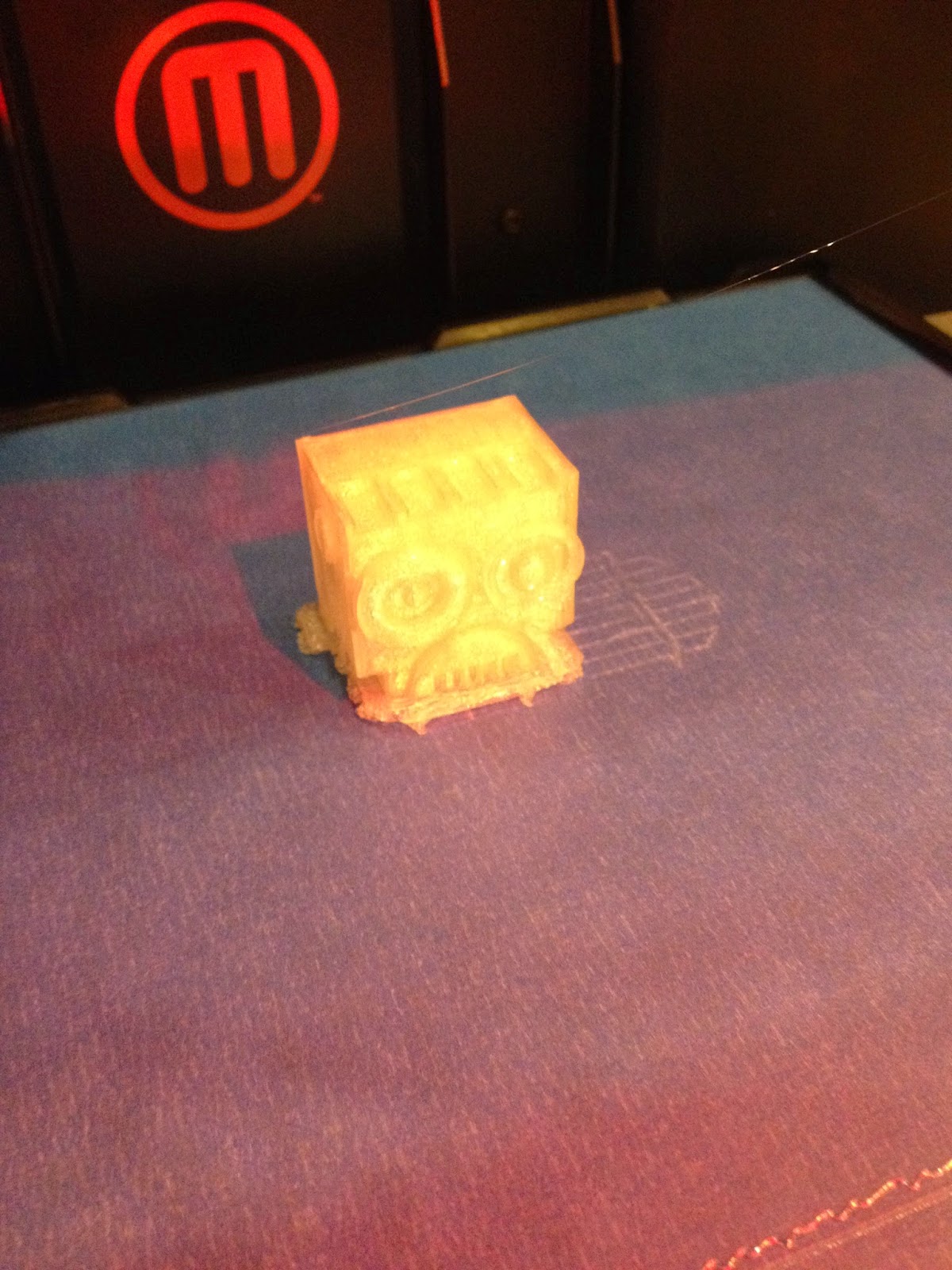

| I made a robot head! More on that soon... |

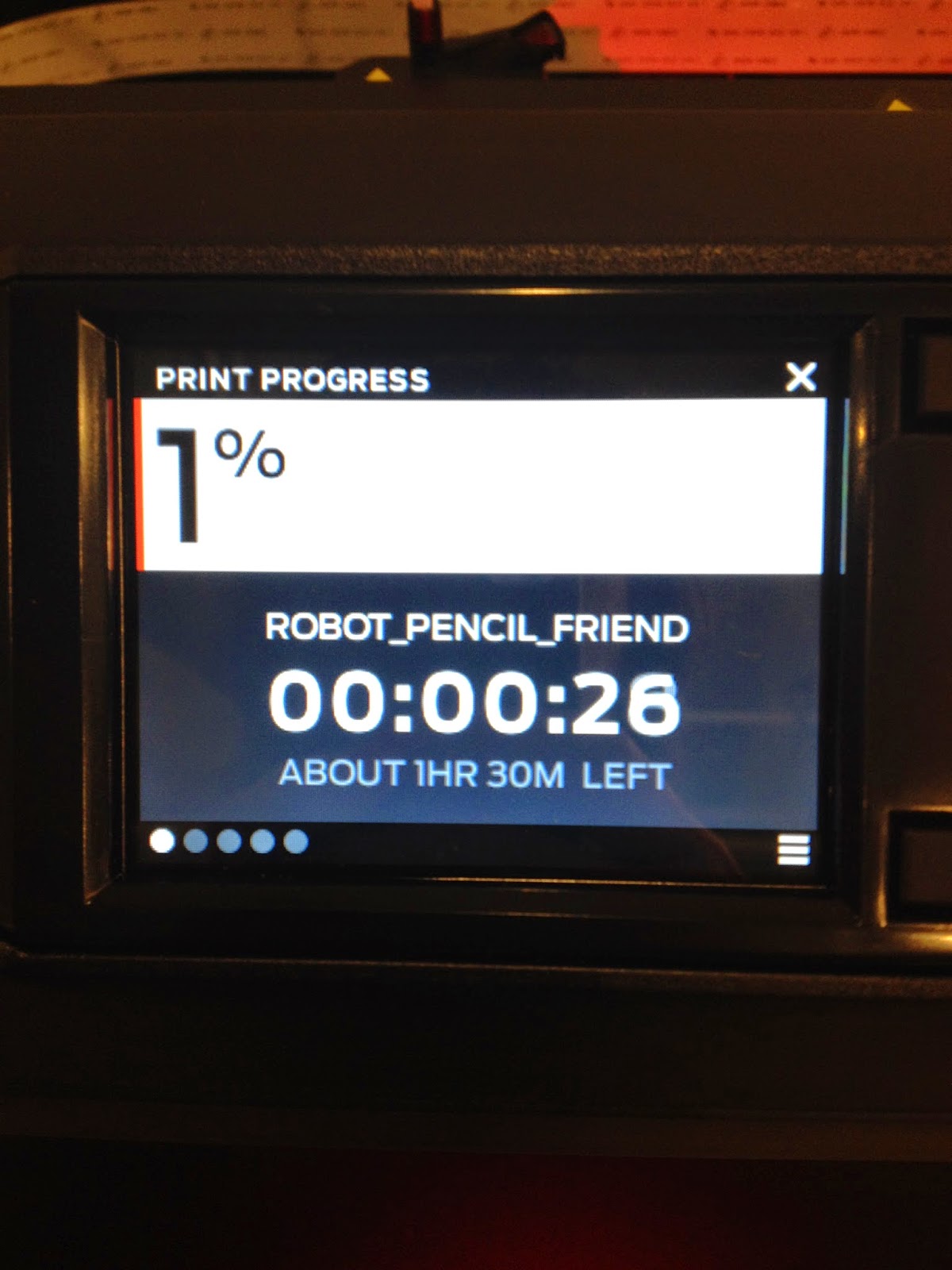

My particular print was estimated to take 1 hour and 30 minutes to complete. In a separate program from Makerbot, I designed a robot head pencil topper. Several programs are coming on to the market for designing prints but most of them are CAD-based software/sites. CAD stands for Computer-aided design and slips into the realms of architecture, product design, and even medical product manufacturing. It is a VERY real-world skill that students can learn and master before they graduate - and we as teachers should be all about relevance and applicable knowledge.

In one of the books I am reading I was provided a step-by-step lesson in

TinkerCAD, an online 3D modeling program specifically for printing projects. It was a super simple interface and TinkerCAD even offers classes to help you learn how to move, scale, rotate, and connect objects. As you take classes, you gain experience and new classes are made open to you. You can learn how to make name tags, dice, bracelets - the list goes on! I only did the basic classes to become more familiar with the commands and controls. TinkerCAD provides basic shapes to design with and allows you to create holes as well as group objects to form one big shape. I would incorporate the art concepts of shape, form, perspective.. the list goes on and on! The important thing is that students are experiencing spatial reasoning and coming to understand how the shapes interact and connect to each other while they are creating something really cool and original in the process! I think the robot head pencil topper would be a great starting project for students and I will provide instructions for it to my audience at the conference... just in case they are interested in trying out TinkerCAD themselves! Anyway... yeah, I made a robot head!

|

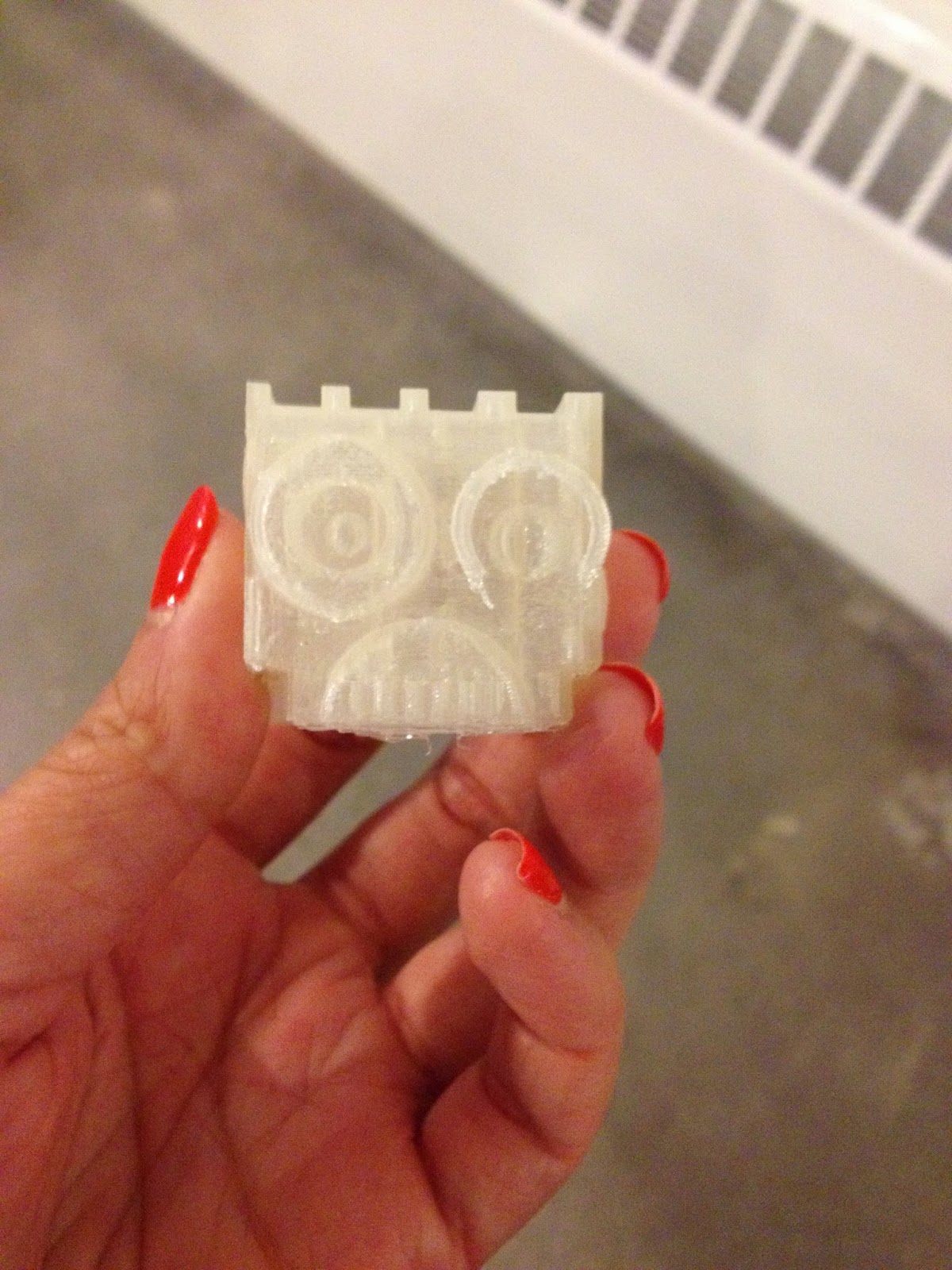

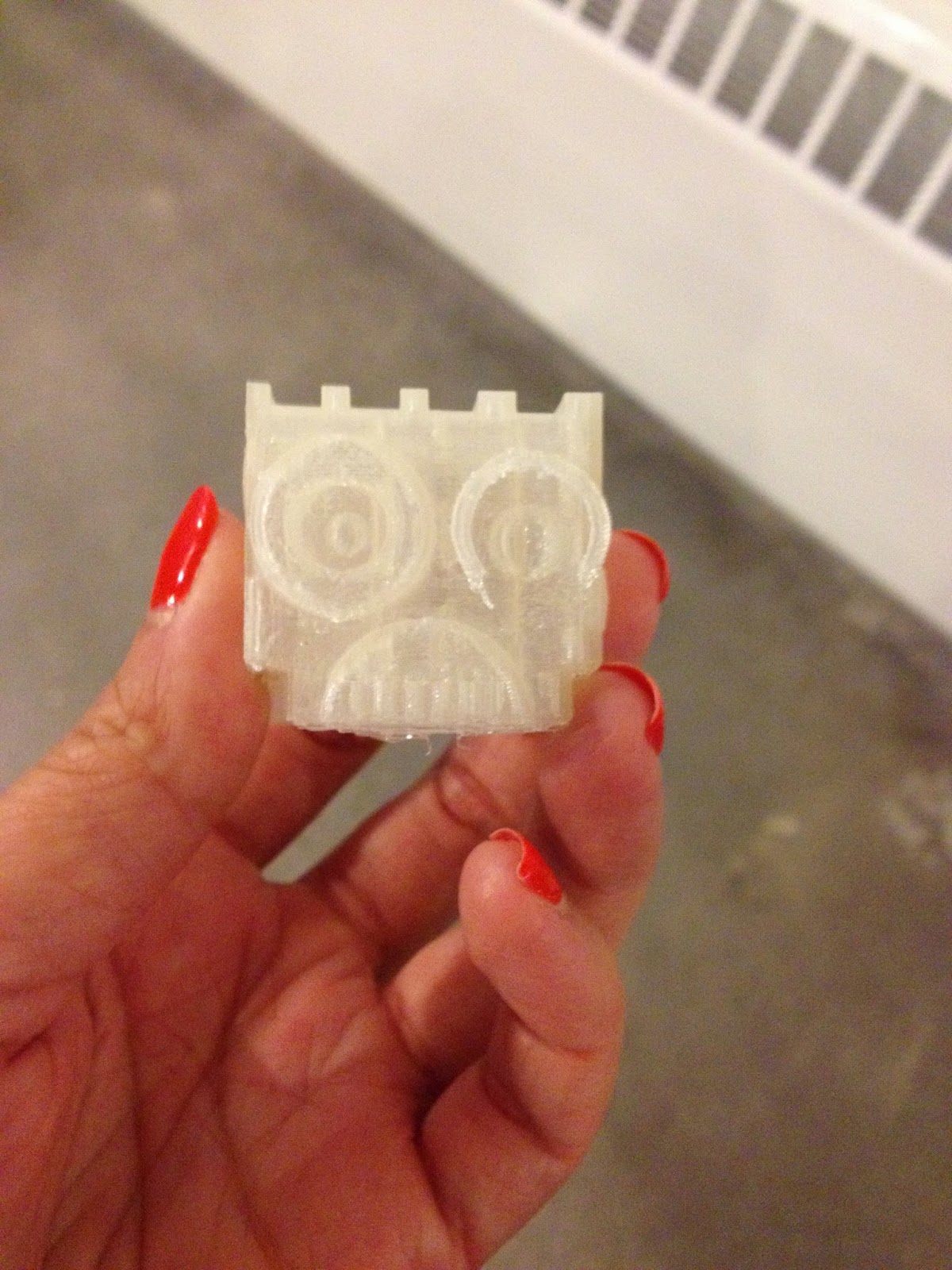

| my robot friend :) |

One thing you need to know about 3D printing.... the size of objects is crucial. As in any other manufacturing process, the larger and more complex your object or product is, the longer it will take to print and produce. That being said, my little robot dimensions were given in millimeters! Talk about a tiny print.. but in terms of a teaching moment, this would be perfect for math teachers! Or overzealous teachers in other subjects, I suppose - converting millimeters into inches would give students an idea of the size of their final prints and they would also be able to scale up or down to their desired print size. I was lazy and used an online converter. Bad... but for lack of time I made do. Students could also learn about perimeter, calculating volume, and rounding up numbers...

A smaller print will take less time, but if it has more detail you have to account for that extra work the computer/printer will have to do to make a clean print! I made lots of details on mine (bolts, rings, holes..) and it added extra minutes to my final print time. Keeping that in mind, size does matter and detail even more so! The inside of the robot head was hollow with walls on all sides. There was a smaller, round hole in the middle for the pencil to be inserted into and I learned a LOT about wall thicknesses before even thinking about printing... that was a tricky part of the design process. Figuring out placement of holes and walls. But I figured it out eventually.

|

| the waiting... tick tock |

Again, my print was set to take about an hour and a half so I settled in for some careful observing and worked on taking notes and other projects.. this would be a downside to printing in the classroom. THE WAITING! No kids like to wait.. and frankly neither does Ms. K! So if incorporated into an active classroom, the 3D printer would be going at all times, printing multiple projects at once.. And someone should be present when the printer is running. Aka DO NOT leave your printer unattended overnight to make that spongebob figurine so and so wanted because you could have a serious mess or worse on your hands! 3D printers should be treated as a machine to be respected and given distance. They get HOT and should be monitored. One cool feature on this particular Makerbot model is the extruder camera - yep! You can actually stream live video from your printer to your computer to watch your print being made! Something appealing for keeping track of different prints and showing students the printing process.

|

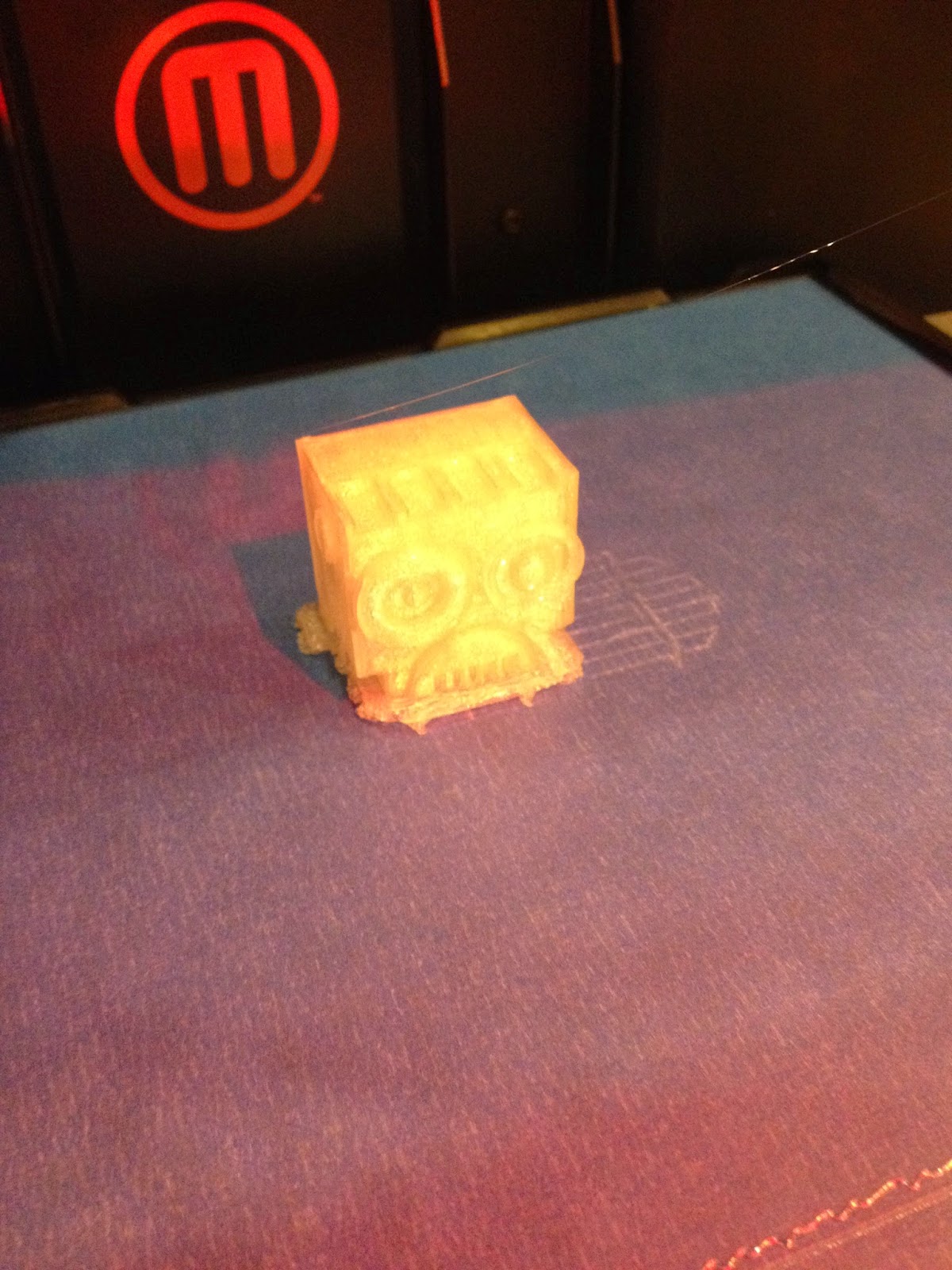

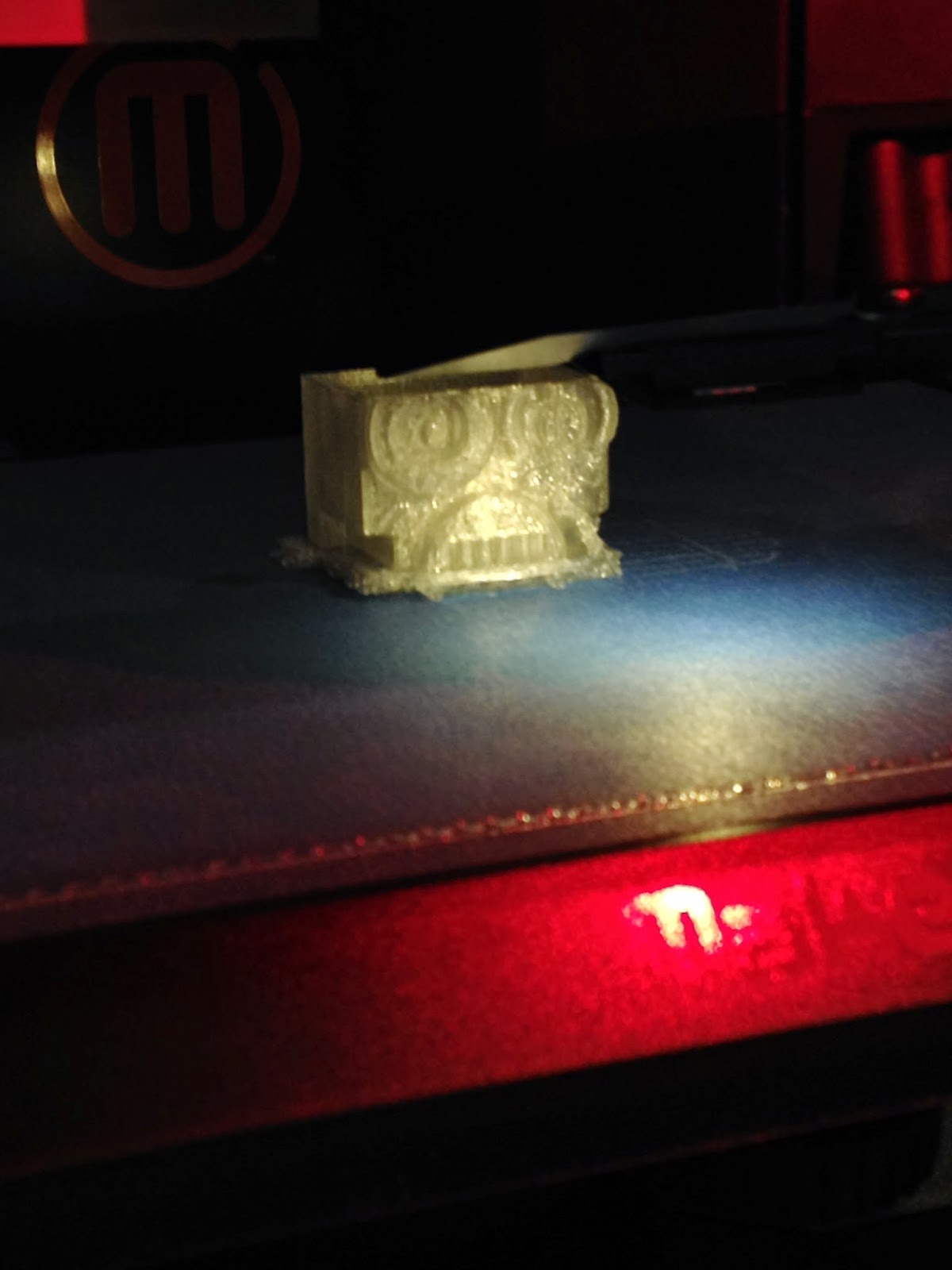

| about 3/4ths of the way into the printing process..so close! |

|

| my finished print! ready to be unattached from the print plate |

One hour and 30 minutes later, my robot pencil topper was completed! To remove the print from the plate, my teacher and I used a scraper to gently peel off the PLA from the tape surface. Kind of like scraping ice off of a windshield, but with less swearing and frustration haha

As stated before, the inside of my robot was hollow, but I had a problem. One of many topics stressed in my research is the importance of failure and learning from mistakes. Well.. I didn't completely fail, but I did realize my errors. For starters, when constructing the robot head I had to insert a 'hole' cylinder into the middle for the pencil to fit. At a later stage, I needed to create a hollow top, which would decrease the print time and also allow for some literal wiggle room for the printed bot on top of the pencil. The problem was I made my walls very thin and also made the top of the robot (top wall) too far away from the side walls. This meant that my robot sat crooked on the pencil top because there was too much space surrounding the pencil on the inside!

Talk about planning... 3D printing is ALL about spatial reasoning, planning, calculating sizes, learning from mistakes, internal volume, design.. it's a mixed bag of educational concepts. AND to top it all off it's a really fun way to create 3D objects and bring them to life with technology - to hold in your hand or stick on your pencil eraser! Again, I would probably utilize this lesson as an introduction into CAD programs and 3Dprinting. I would be able to do multiple prints at one time - depending on sizes and how big my print area was - and that would give the students who needed extra time to design or extra help the chance to work on their robots while the other designs print.

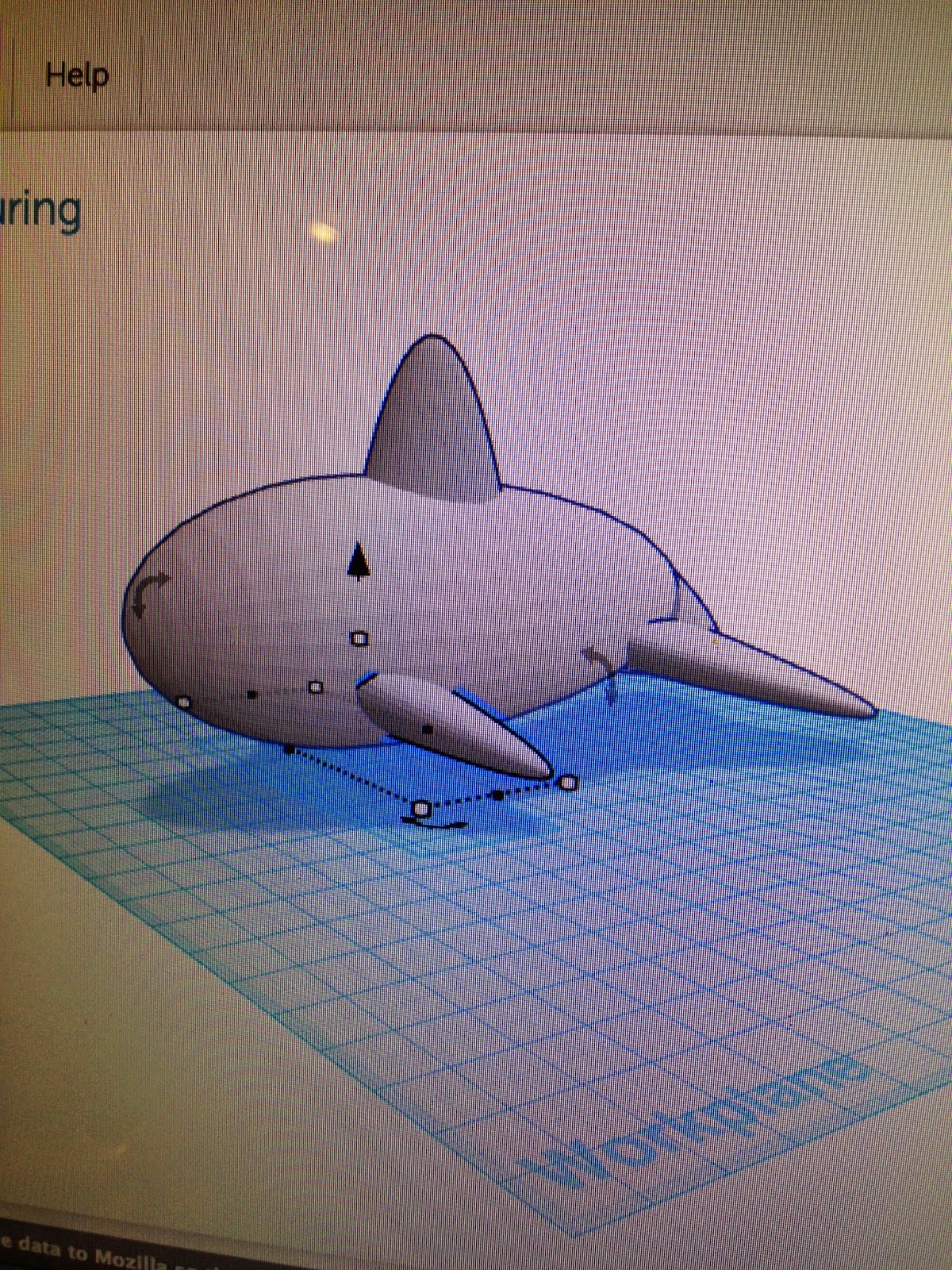

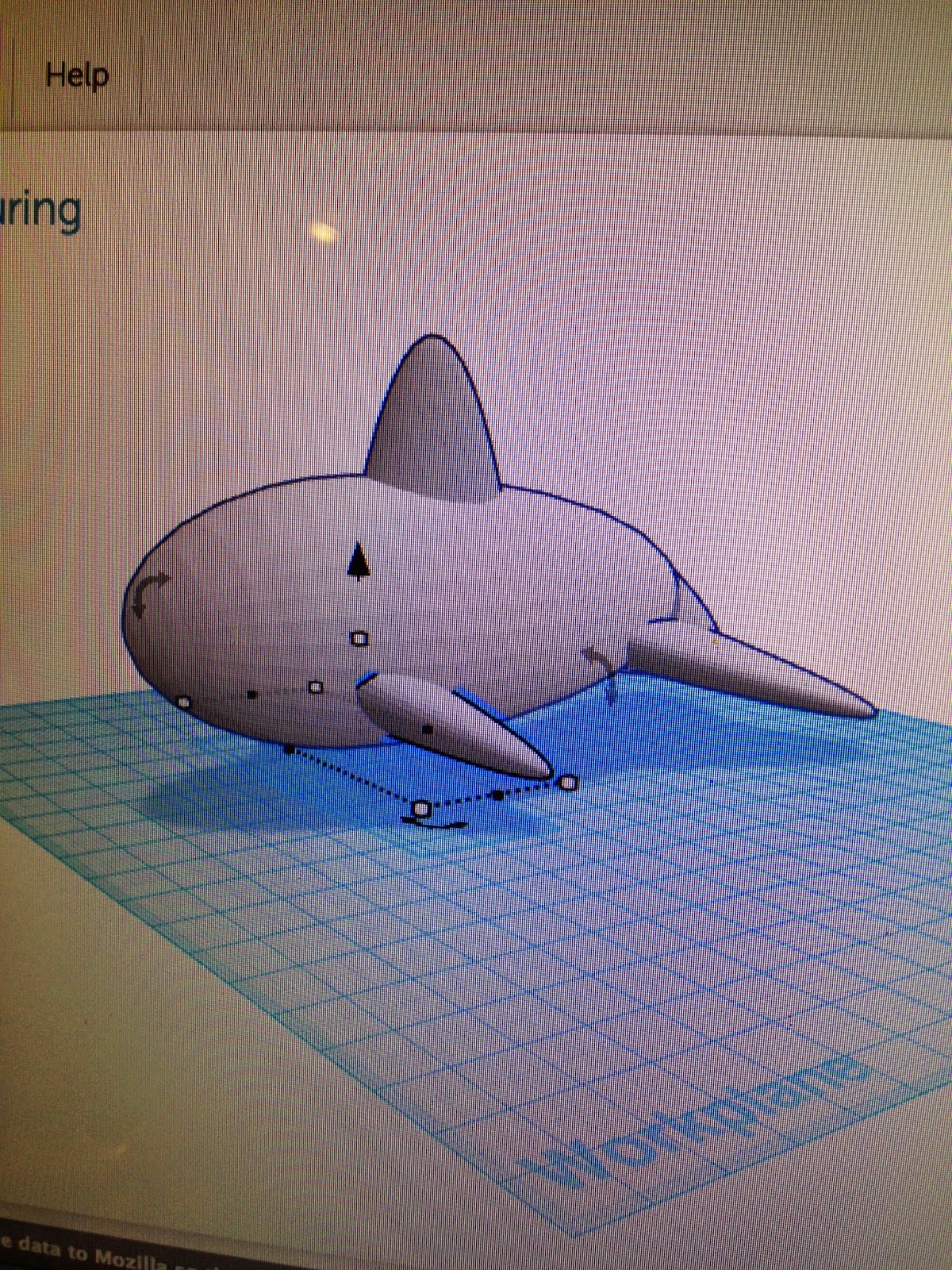

Time management was a big aspect of printing, too! Again, a great skill to teach students.. and adults for that matter. I spent about 45 minutes creating my robot in TinkerCAD and then had to wait for the hour and a half for it to print.. in that time I was able to start designing a new print which utilized more rounded-off objects like eggs, spheres, and ovals. What will be interesting is when I actually print it. There will be a lot of support material needed to hold up the different curves and edges of the shapes. The only way to find out is to do! I will also be making this model hollow to cut down on print time, like I did with the robot head.

|

| whales are kind of my thing..one of many. |

Overall I chalk up this experience as a success! I learned a great deal about the print process, planning designs, and finally troubleshooting for future prints. 3D printing as a teaching tool could go miles in hands-on learning instruction. Over the next few weeks I will be making time to return to the Design Lab and creating different types of prints to try on the Makerbots. My professor gave me his office hours and the go-ahead to do all the research and playing I needed to! :) It's pretty exciting. I think I will have quite the arsenal of knowledge and experience to bring to Lansing this fall. In the meantime I need to crack down on painting, photography, graphics.. all that good stuff I signed up for back in the beginning of the year! One more year of classes and then I am student teaching FINALLY. Perhaps by then I will be settled in to a school and ready to start 3D printing with my own students... I can only hope :)

Until next time!

Ms. K

Talk about planning... 3D printing is ALL about spatial reasoning, planning, calculating sizes, learning from mistakes, internal volume, design.. it's a mixed bag of educational concepts. AND to top it all off it's a really fun way to create 3D objects and bring them to life with technology - to hold in your hand or stick on your pencil eraser! Again, I would probably utilize this lesson as an introduction into CAD programs and 3Dprinting. I would be able to do multiple prints at one time - depending on sizes and how big my print area was - and that would give the students who needed extra time to design or extra help the chance to work on their robots while the other designs print.

Talk about planning... 3D printing is ALL about spatial reasoning, planning, calculating sizes, learning from mistakes, internal volume, design.. it's a mixed bag of educational concepts. AND to top it all off it's a really fun way to create 3D objects and bring them to life with technology - to hold in your hand or stick on your pencil eraser! Again, I would probably utilize this lesson as an introduction into CAD programs and 3Dprinting. I would be able to do multiple prints at one time - depending on sizes and how big my print area was - and that would give the students who needed extra time to design or extra help the chance to work on their robots while the other designs print.